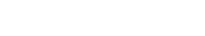

1. Intelligent control and operation optimization: wide load peak regulation and AGC characteristic optimization (DCS intelligence upgraded to ICS)

■ Key technologies

(1) Low load steady burning and AGC fast response module;

(2) Primary frequency modulation and CCS feature enhancement module;

(3) Heat-power conversion and decoupling problems, fuel calorific value correction;

(4) Low-load adaptation modules;

(5) Unit inertia correction module.

■ Expected effect

(1) AGC\ primary frequency modulation upgrade qualification rate>90%; annual power grid award of about 8 million RMB;

(2) Improved energy efficiency of the unit, reduced system power consumption and decreased smoke loss and ammonia injection amount, to realize annual income about 500k RMB;

(3) Achieve AGC and primary frequency modulation under minimum stable burning, to be granted by 30 million RMB for peak regulation.

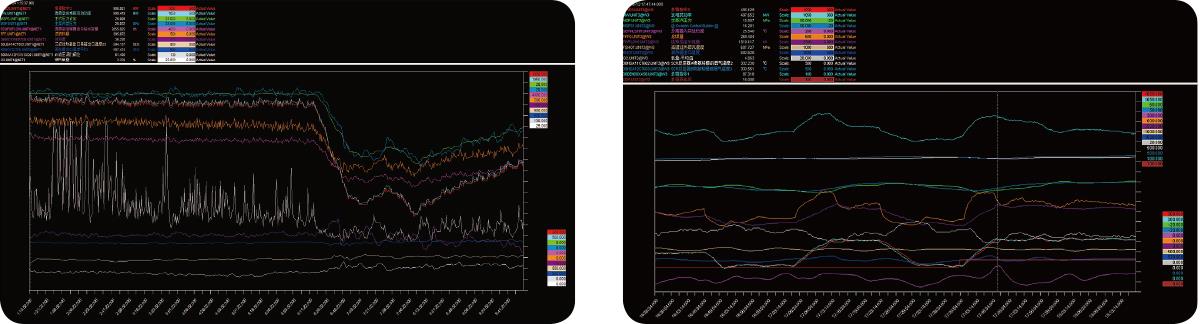

2. Intelligent control and operation optimization: visualized boiler chamber intelligent safety monitoring and optimized burning system

■ Key technologies

(1) Real-time dynamic boiler chamber temperature field distribution and smoke composition change, establish dynamic data model of furnace temperature field and smoke composition;

(2) Real-time diagnosis with three dimensions (safety, efficiency, environmental protection) on boiler chamber burning, AI control on dual-scale burning process, multi-source intelligent burning optimization control;

(3) Intelligent judgment of boiler chamber temperature field, CO, CO2, NOx and burning intensity spectrum, and intelligent burning optimization and adjustment.

■ Expected effect

(1) Achieve 30% low load steady burning problem, to prevent unstable burning MFT;

(2) Reduce NOx at the boiler chamber outlet by at least 25%, and save ammonia consumption by 30%;

(3) Dynamically regulate the burning process, flatten the temperature peak, effectively formulate coking, and improve combustion efficiency by about 0.5%;

(4) Comprehensively considering contributions on safety, load, ammonia consumption and power grid awards, the yearly income is no less than 8 million RMB.

3. Intelligent control and operation optimization: micropower-based multi-source intelligent sliding pressure optimization system

■ Key technologies

(1) High-pressure cylinder governing valve flow characteristic test and dynamic calculation of throttling loss; combined power consumption model of high-pressure cylinder efficiency and high-pressure cylinder governing valve; matching calculation model of feed pump power consumption and high-pressure cylinder governing valve throttling loss;

(2) High-pressure cylinder governing valve loss, high-pressure cylinder efficiency and boiler reheater desuperheating water coupling model and economic accounting;

(3) Simulation of coal consumption big data coupled valve position self-adaption optimal sliding pressure curve model.

■ Expected effect

(1) Establish the optimal sliding pressure curve and dynamic adaptation model of the unit to improve the overall efficiency of the unit, contributing about 1 million RMB annually;

(2) Support the AGC flexibility and primary frequency modulation capability of the unit, and improve the “load-varying spot transaction” capability by 40%, contributing about 7.5 million RMB annually;

(3) Support improvement of the primary frequency modulation capability and obtain the power grid reward. In combination with increase in energy efficiency of the unit, AGC following capability and the primary frequency modulation, the annual contribution is no less than 8.5 million RMB.

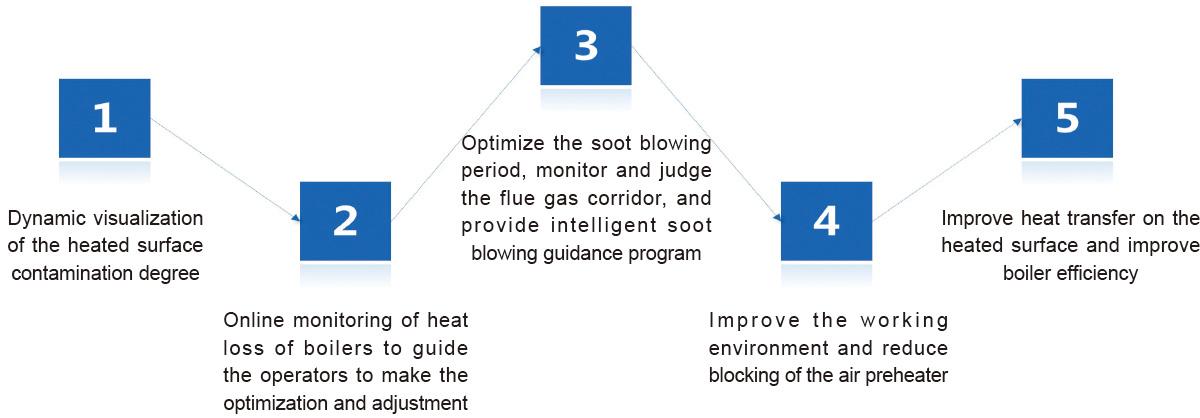

4. Intelligent control and operation optimization: dynamic heat load based multi-source coupled intelligent soot blowing system

■ Key technologies

(1) Cleaning factor and fouling factor test accounting, process mechanism modeling; statistical modeling of key indicators;

(2) Temperature field distribution and thermal process correlation model, process accounting and triggering engine; thermal process causal modeling;

(3) Safety, environmental protection and economy 3D mechanism model triggering engine; system correlation data, environmental parameter mapping model;

(4) Smoke corridor mechanism, judgment characteristics, mechanism and judgment big data model engine; multi-source coupling modeling and simulation.

■ Expected effect

(1) Reduce steam consumption after intelligent soot blowing by 30% to prevent over-blowing accidents;

(2) Support boiler system optimization and increase boiler load capacity by 30%;

(3) Effectively support the body maintenance strategy, improve boiler efficiency by 0.3%, and increase annual revenue by approximately 1.26 million RMB;

(4) Eliminate boiler coking and flue gas corridors, and avoid local smoke exhausting. Considering steam saving, boiler efficiency and load contribution, the annual comprehensive income is about 5 million RMB.

5. Intelligent control and operation optimization: steam turbine cold end intelligent diagnosis and optimization decision system

■ Key technologies

(1) Establish research and judge models and the optimization knowledge base of additional heat load, condenser heat transfer, vacuum tightness, and rubber ball system;

(2) Establishing the performance proofing model and maintenance optimization knowledge base of condenser cooling rate, water tower filling /water distribution pipe, and vacuum pump related systems;

(3) Establish a characteristic matrix model and optimization knowledge base for the dynamic efficiency curve and micropower variation of the condenser.

■ Expected effect

(1) Knowledge base engine for optimal control of the steam turbine cold-end system, automatic research and judgment system, equipment failure, performance characteristics;

(2) Automatically recommend the best operation mode and maintenance suggestion decision, realize standardization of operation and maintenance management, and improve control efficiency by 50%;

(3) Reduce the maintenance cost by 20%, and increase vacuum by 0.5kPa, to realize annual income no less than 1.8 million RMB.

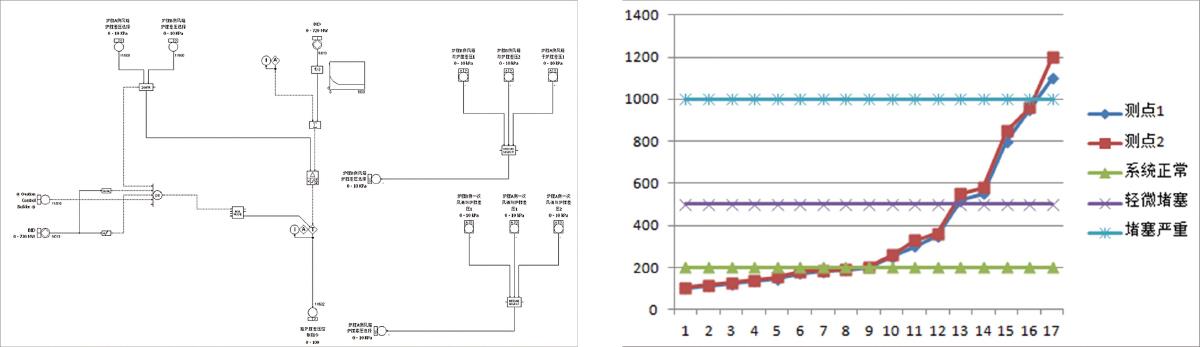

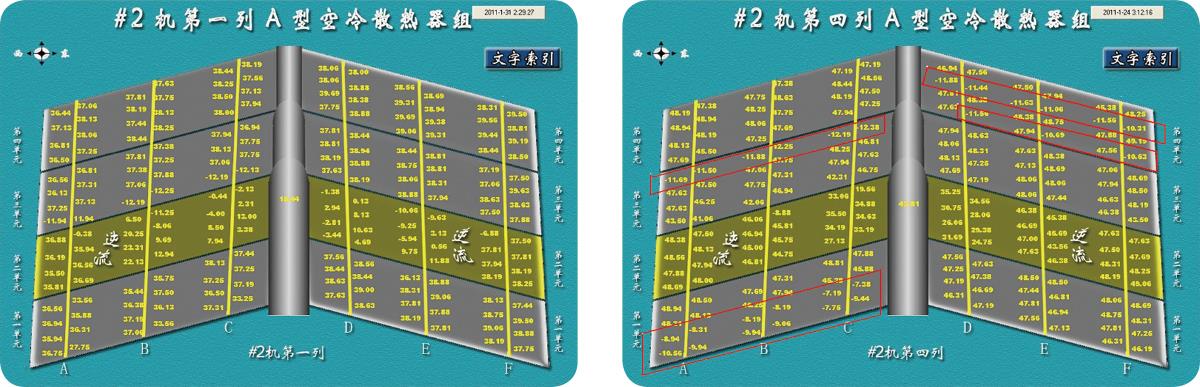

6. Intelligent control and operation optimization: 4S coupling based air preheater intelligent optimization and safety pre-control system

■ Key technologies

(1) Early fire dynamics judgment and preheater blockage dynamic analysis model;

(2) 4S research and treatment model for air preheater corrosion and blockage mechanism trend;

(3) Establish air preheater dynamic pressure regulator and air leakage rate optimization big data model;

(4) Air preheater rotor expansion deformation dynamic model and rotor jam pre-control model.

■ Expected effect

(1) Control early fires to prevent fire accidents, so as to avoid losses of more than 1 million RMB;

(2) Pre-control corrosion blockage, reduce fan power consumption, and extend operating cycle, to contribute about 1 million RMB per year;

(3) Assist with operation decision, reduce exhaust smoke temperature, and increase efficiency by about 0.2%;

(4) Overloading and special working conditions to prevent accidents caused by expansion and deformation of rotors, to avoid loss of about 500k RMB;

(5) The annual comprehensive benefit is about 2.84 million RMB.