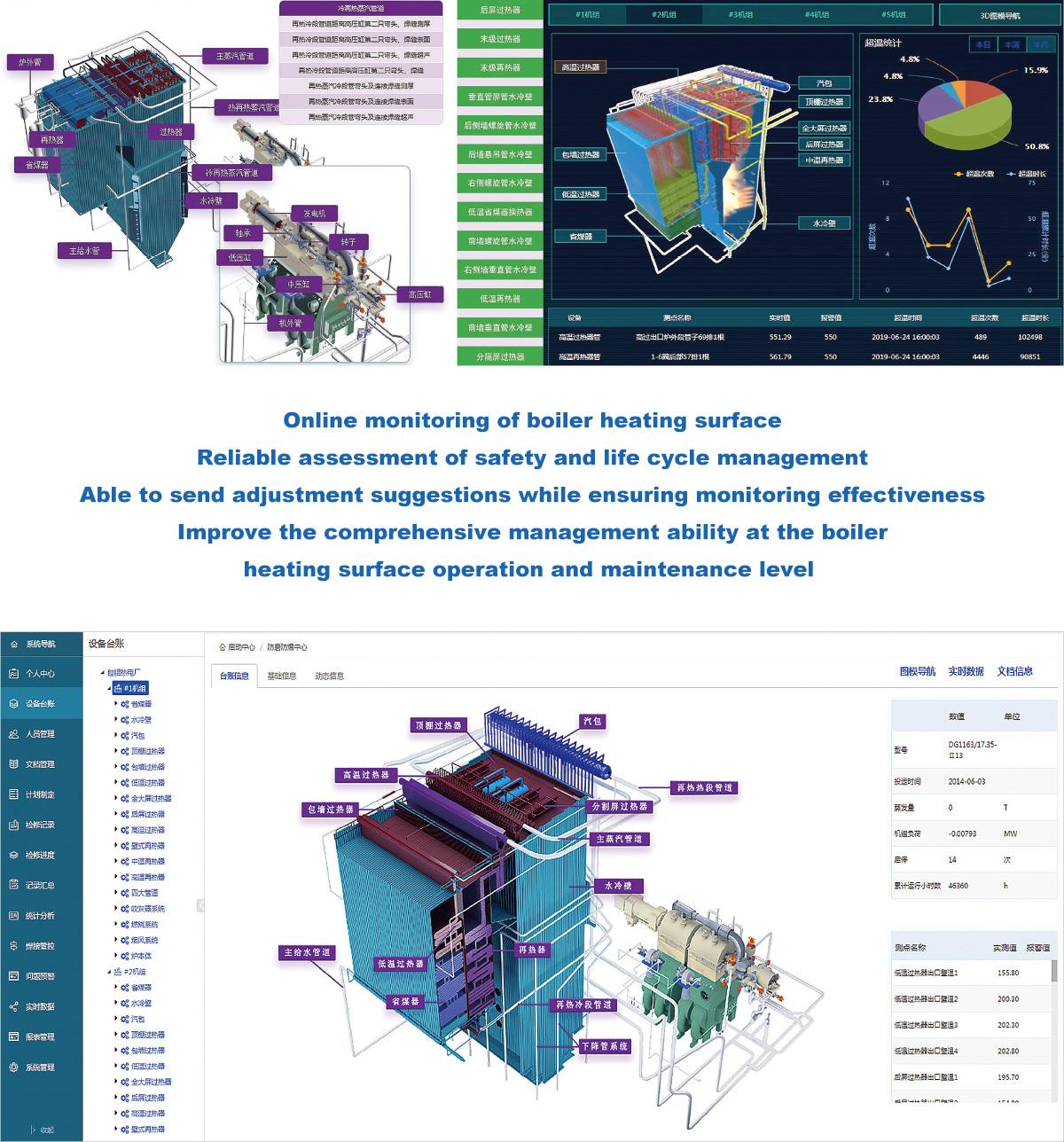

Visualized boiler anti-wear and explosion-proof intelligent safety pre-control system

■ Key technologies

(1) 3D dynamics of heating surfaces of the four tubes of the boiler, digital twinning coupled with online and offline data, automatic sending of the risk of wear, deterioration and failure of the four tubes;

(2) Mechanism model of life and wear of four tubes and AI of big data expert knowledge base;

(3) Configure special sensors and special monitoring instruments.

■ Expected effect

(1) Establish a heating surface wear mechanism model and a hybrid model test;

(2) Intelligent planning of four-tube inspection items reduces the monitoring cost by 50%; optimization of boiler overhaul to generate at least 48 hours of start-up time;

(3) Innovative anti-wear and explosion-proof management and control mode realizes dynamic visualized supervision, reduces boiler accidental pipe burst accidents by more than 80%, and indirectly generates annual income of at least 7.5 million RMB.