Intelligent IoT based high-voltage electrical intelligent monitoring and safety pre-control system

1. Visualized transformer substation intelligent safety pre-control system

■ Key technologies

(1) Remote IR thermal image monitoring and analysis and diagnosis effectively monitors and diagnoses surface contamination defects of porcelain insulators;

(2) High-sensitivity IR thermal imager, high-precision cloud platform accurate positioning and analysis and diagnosis;

(3) IR thermal image and visible light dual mode common platform;

(4) Arrange a number of IR/visible light intelligent cloud platforms to achieve global coverage without dead zones;

(5) Analysis and diagnosis engine performs intelligent diagnosis on historical data, design data, and minor anomalies.

■ Expected effect

(1) Unmanned monitoring of joints/clamps/actuators, early warning of the defective edge of the isolation knife blade and contact piece and joints between the rotating cap and the ball head;

(2) Diagnostic CT of poor connection between the center and outer center, body and oil insulation, and abnormal and overheating of inner center cores and coils of primary components;

(3) Diagnostic PT of abnormal and overheating of insulating oil and inner center cores/ coils and the poor oil insulation and oil insufficiency (low oil level) of coupling capacitors;

(4) Discover early defects of the transformer substation equipment, give alert and send treatment strategy to effectively prevent accidents from deteriorated faults;

(5) Prevent accidents of primary transformer substation equipment, contributing at least 10 million RMB.

2. Visualized high-voltage main transformer intelligent safety pre-control system

■ Key technologies

(1) Apply the principle of electromagnetic oscillation to fault diagnosis;

(2) Introduce the transformer core grounding micro-current intelligent monitoring technology to discover micro-discharge;

(3) Make deep development of the transformer chromatography online intelligent diagnosis function;

(4) Develop expert knowledge base of faults inside and outside the transformer and establish an analysis and diagnostic model for electromagnetic oscillation, chromatographic online and micro-current multi-source coupling.

■ Expected effect

(1) Realize acquisition and orientation analysis of the electromagnetic oscillating signals applied on the transformer;

(2) Continuously collect the degradation information of the transformer insulating oil components, intelligently analyze the chromatographic information characterizing the internal fault of the transformer, and accurately determine the internal electrical fault of the transformer;

(3) The grounding micro-current module, with the custom-developed micro-current sensor, can capture the internal and external discharge faults of the transformer in time;

(4) Prevent accidents of equipment of the main transformer, with direct contribution at least 10 million RMB.

3. Visualized high-voltage factory switch intelligent safety pre-control system

■ Key technologies

(1) Capture the overheating abnormality of the switch mechanism and make timely analysis and warning;

(2) Capture the sparking discharge fault and make intelligent analysis and warning;

(3) Multi-technology coupling to accurately lock internal faults of the switch.

■ Expected effect

(1) Intelligently analyze and monitor such faults as poor connection between connecting parts in the high-voltage switch cabinets and abnormally increased contact resistance;

(2) Accurately monitor partial discharge failure of high-voltage electrical equipment;

(3) Prevention of one high-voltage plant switch explosion accident will contribute at least 3 million RMB.

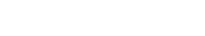

4. Visualized generator excitation slip ring intelligent safety pre-control system

■ Key technologies

(1) IR sensors arranged surrounding the carbon brush and the slip ring, in combination with ultrasonic and surface wave acquisition, enables the imaging surface to cover the entire carbon brush slip ring device;

(2) Multiple technical means are coupled to accurately detect early ignition, carbon brush overheating and slip ring erosion;

(3) Accurately transmit abnormal data to the background monitoring system, monitor the overall temperature field in real time, and send the disposal strategy.

■ Expected effect

(1) Realize full-range continuous monitoring of the generator excitation carbon brush and slip ring, to ensure full-range monitoring free of dead angle and breakpoint;

(2) Early warning of carbon brush slip ring early ignition abnormality, monitoring of deterioration trend, real-time sending of early warning information and disposal strategy to prevent malignant accidents of excitation carbon brush;

(3) Prevention of a fire accident of the generator slip ring will make direct contribution at least 20 million RMB.

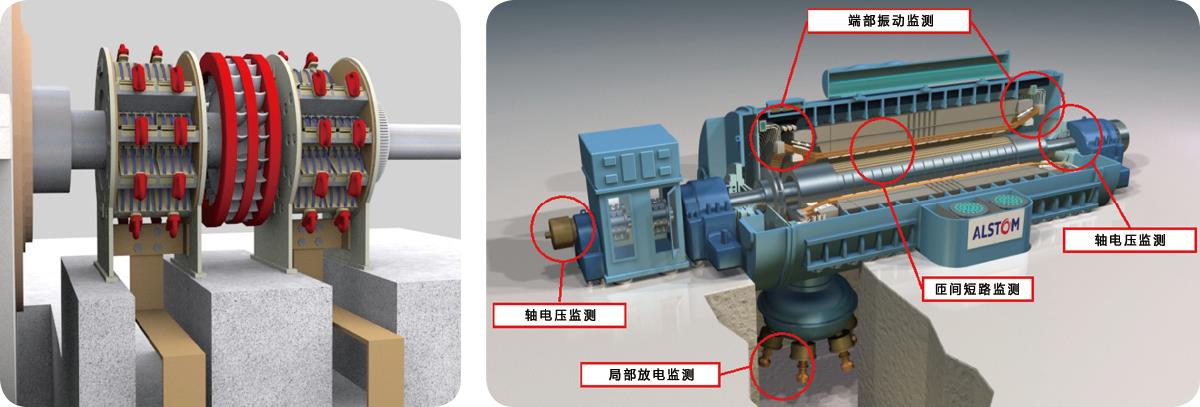

5. Visualized phase modifier intelligent safety pre-control system

■ Equipment fault diagnosis: vibration online monitoring, electrical fault monitoring, cooling system monitoring, oil and liquid analysis, automatic inspection of distribution room, monitoring and control of the power distribution room environment

■ Equipment operation and maintenance: remote synchronization monitoring, intelligent point inspection, operation training, maintenance guidance

■ System fault diagnosis: offline fault diagnosis, online state assessment