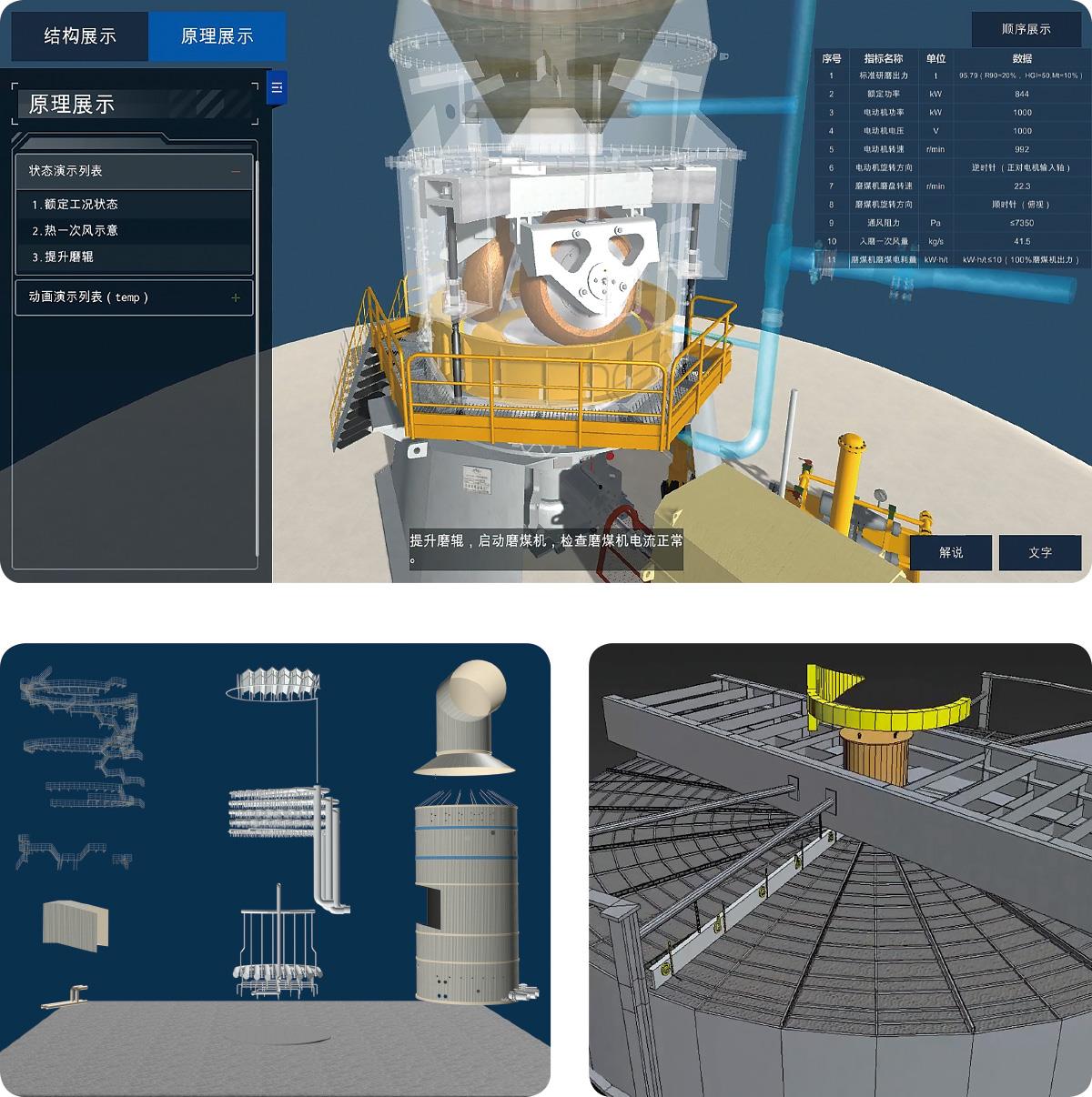

Visualized 3D virtual lean maintenance control system

1. Equipment 3D disassembly guidance training system

■ Key technologies

(1) Digital drawings, equipment component level modeling, dynamic simulation of the operation process and fault type;

(2) Self-developed 3D modeling platform, full-process simulation guidance of equipment 3D disassembly, automatic hints of quality inspection points and dangerous points, full process package and file card.

■ Expected effect

(1) Full-process simulation of inspection and disassembly of important equipment and systems, precise prompt of procedures, quality control points, and dangerous points, improvement of maintenance quality and efficiency by 20%, and reduction of quality accidents by more than 60%;

(2) Refined simulation of the internal structure and operation process of the equipment, full-process visualized training on equipment principles, maintenance process and technical process, effective support of maintenance planning, and save cost of energy-saving personnel training by more than 40%.

2. Visualized 3D virtual lean maintenance system

■ Key technologies

(1) Digital drawings of production and maintenance systems, equipment component level modeling, dynamic simulation of the operation and maintenance process and fault type;

(2) Self-developed 3D modeling platform, full-process simulation guidance of equipment 3D disassembly, adoption of 3D digital twinning technology to realize optimal maintenance of whole system and entire equipment of the unit;

(3) Structured process parameters of the equipment operation and the equipment state parameters are “nested” in the 3D system to realize digital twinning optimization and maintenance optimization of the virtual environment.

■ Expected effect

(1) Realize optimized maintenance and operation optimization of 3D digital twin support for unit A/B/C/D maintenance, and effectively support optimized control of the maintenance cycle, maintenance items and spare parts;

(2) Innovative overhaul and minor repair management mode and equipment training mode to achieve real quality and efficiency improvement, and effectively support streamlined organization and elevate efficiency management objectives;

(3) Reduce the overhaul and minor repair cost by 20%, improve maintenance efficiency by 20%, scientifically optimize the maintenance cycle by 10%, and make comprehensive contribution of at least 8 million RMB.