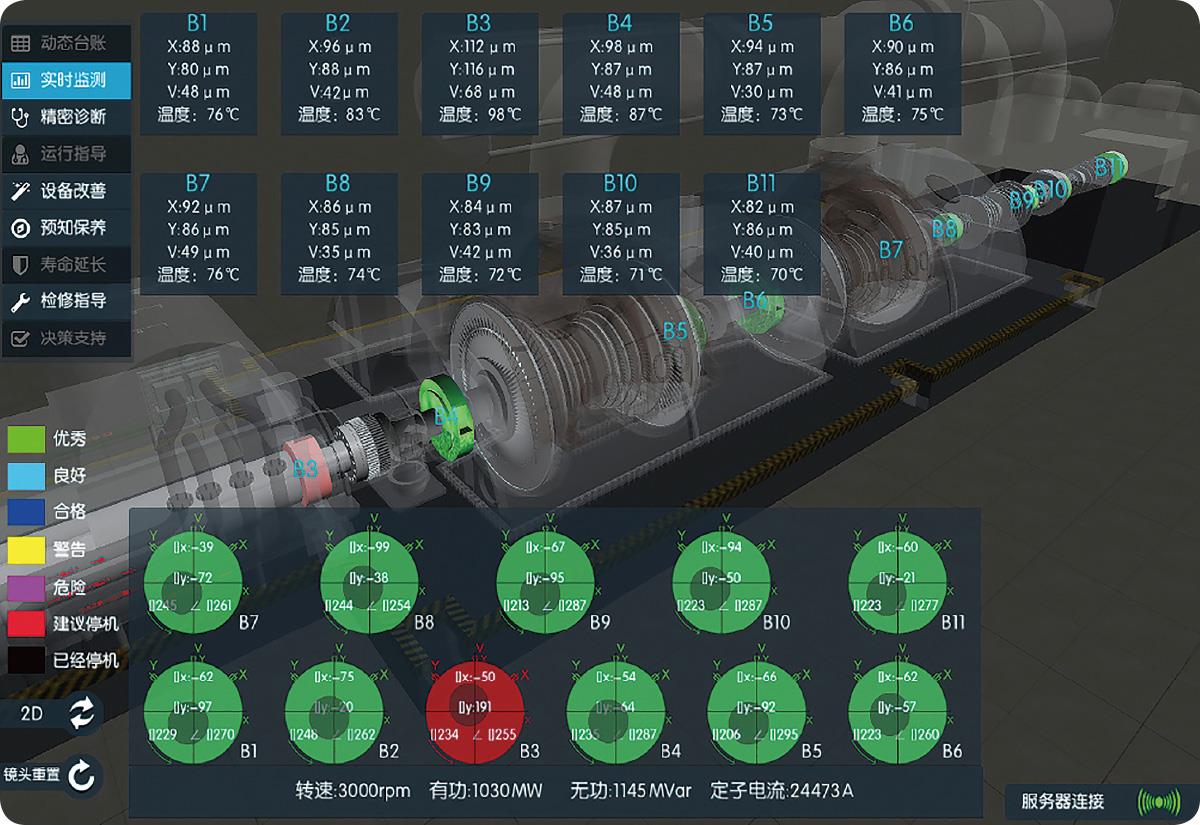

Visualized steam turbine generator set intelligent safety pre-control system

■ Key technologies

(1) Collect steam turbine state characteristic data from TDM, automatically collect fault vector characteristic through the expert diagnosis system, continuous analyze of characteristic matrix changes by the automatic diagnosis engine, and boast of machine self-learning ability;

(2) With the help of the expert diagnosis engine, automatically detect, analyze and judge the running condition, degradation starting point, automatically send maintenance suggestions, and avoid fault trips caused by omitted problems in routine detection, unclear analysis and judgment, and lack of equipment maintenance strategy.

■ Expected effect

(1) Intelligently recommend cold-state rotation-impulsing parameters, display the bearing jacking height in real time, avoid excessive vibration due to skill deviation and bearing bush damage;

(2) Analyze TSI data in real time, intelligently analyze small changes, avoid disturbances and repetitions of shafting changes after overhaul, shorten start-up time by 24 hours;

(3) Accurately lock the reasons behind “the first tripping condition occurred”, such as protection misoperation, unbalance, thermal bending and oil film instability, intelligently send the inspection and verification strategy, and grasp the “golden time” for stating in the extreme hot state, and enable load running with an average of 12 hours ahead;

(4) Based on the above analysis, the contribution of each system startup is no less than 1 million RMB, and the scientific decision-making contribution after the overhaul even reaches 10 million RMB.

Revolutionary contribution in the field of vibration fault diagnosis of steam turbine generator units

The world's first visualized steam turbine monitoring system

Steam turbine fault diagnosis accuracy > 90%

Upgrade of TDM + ES

Eliminate serious accident of steam turbines

■ Shaft state visualization (original)

■ Automatic fault diagnosis and display (original)

■ Operation guidance and troubleshooting suggestions (original)

■ Journal bearing design optimization recommendations

■ Steam turbine visualized regulation valve sequence optimization

■ Professional vibration spectrum (traditional TDM)